Pump Control Automation

Real-time processing, integrated the monitoring to the Medium Voltage Circuit Breaker status and data management function.

Main Features

- The new generation of Underground Mines Pump Station Automatic Control System developed by KAICHENG was based on the plentiful experiences that KAICHENG servers underground mines in past years, and uses advanced control unit to achieve the real-time processing, and high reliability, as well as the flexibility of system expansion and upward connection capability.

- Integrated the monitoring to the Medium Voltage Circuit Breaker status.

- Integrated data management function, including operation hours and status of each pump, fault/alarm report, and power consumption with power demand analysis per 24 hours.

- Operation condition, and runs full pumping when water level above warning point. The water level is monitored and is set in the control system as Low, High, and Warning. When the level at Low and lower, pumps are stopped, when the level at High, two of pumps are going to run while two as backup and one leaves as maintenance, when the level achieves Warning, three of pumps run while the rest leaves as backup (for example there are five pumps in total). Under the condition that the level under Warning point, pumps can be controlled also according to the peak/valley of power supply.

- Control mode have Remote, Local, Auto, Manual, and Maintain.When the control mode is set to Remote, the main control room aboveground can control the pumps directly.

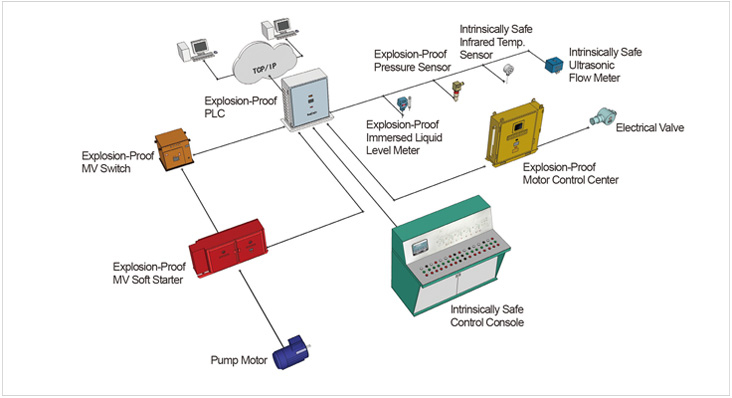

System Configuration